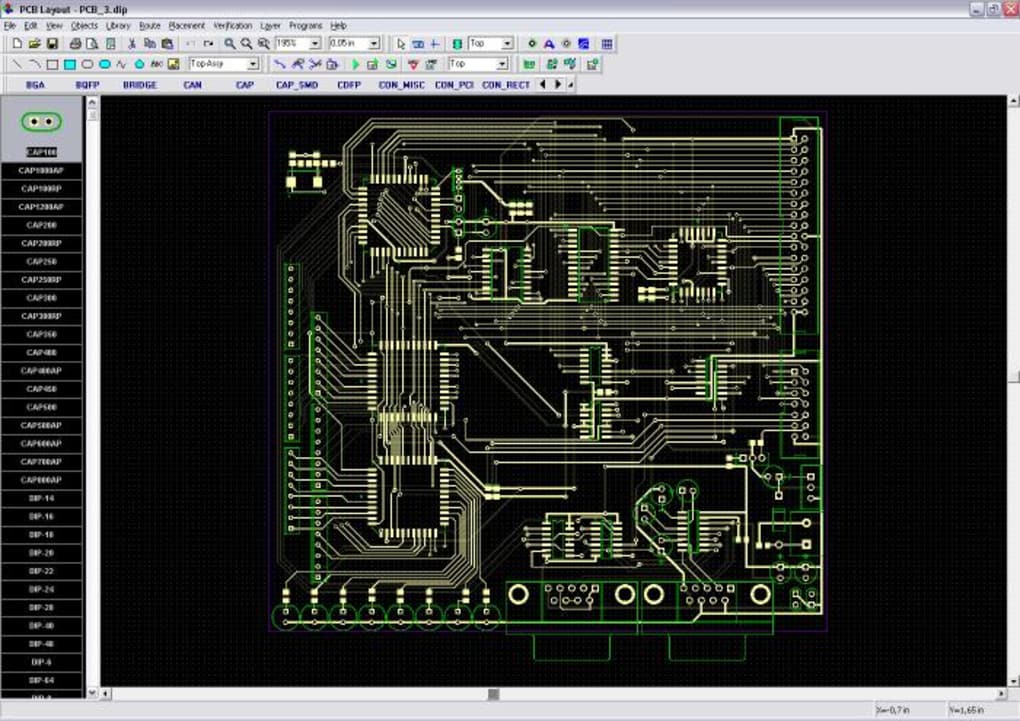

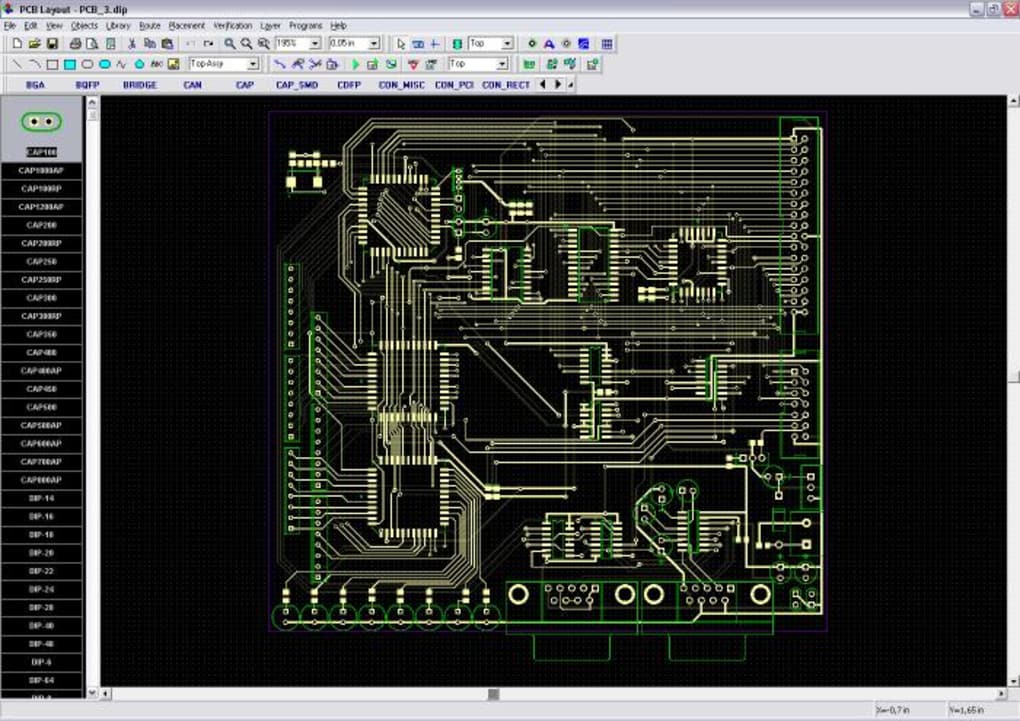

Note: PCB width and height has to be added to offsets to avoid negative component origins. IdeallyĪny good machine should have a setting for PCB thickness.

Head places the component it does't push it down so far, this can help if your PCBs flex when placing parts. Note for the CHMT machines: Using a Z offset simply adds the offset to the height of each component, so that when the

Apply a 0.5mm Z offset to when placing parts. Pnpconvert -i examples/example1.csv -o example1-270-with-rails -r 270 -rx 70 -ry 0 -ox 105 -oy 75 -c  Rotate example1 270 degrees and add 5mm rails. Pnpconvert -i examples/example1.csv -o example1-90-with-rails -r 90 -rx 70 -ry 0 -oy 5 -ox 5 -c Rotate example1 90 degrees and add 5mm rails. Pnpconvert -i examples/example1.csv -o example1-90 -r 90 -rx 70 -ry 0 -c U1 is at the PCB origin but in the CSV file it's coordinates are relative to the bottom left component. When exported "Use PCB origin" was NOT selected, so the bottom left component has a position is closest to 0,0. If an argument is specified more than once, the first occurrence applies.Įxample1 has board width of 70 and height of 100, PCB origin is the center. PnPConvert also supports reading one or more files containing arguments, prefix each filename with an symbol.Īrguments are processed in the order they appear. s= pcb side (top|bottom|all), default is all Replace components by refdes ("refdes,value,name"[ r= rotation degrees (positive is clockwise) oz= Z offset, applied to all component heights. m= mirroring mode (horizontal/vertical/both/none), dr= Disable components by refdes (comma separated list) cfg= configuration file (in "key=value" format)

Rotate example1 270 degrees and add 5mm rails. Pnpconvert -i examples/example1.csv -o example1-90-with-rails -r 90 -rx 70 -ry 0 -oy 5 -ox 5 -c Rotate example1 90 degrees and add 5mm rails. Pnpconvert -i examples/example1.csv -o example1-90 -r 90 -rx 70 -ry 0 -c U1 is at the PCB origin but in the CSV file it's coordinates are relative to the bottom left component. When exported "Use PCB origin" was NOT selected, so the bottom left component has a position is closest to 0,0. If an argument is specified more than once, the first occurrence applies.Įxample1 has board width of 70 and height of 100, PCB origin is the center. PnPConvert also supports reading one or more files containing arguments, prefix each filename with an symbol.Īrguments are processed in the order they appear. s= pcb side (top|bottom|all), default is all Replace components by refdes ("refdes,value,name"[ r= rotation degrees (positive is clockwise) oz= Z offset, applied to all component heights. m= mirroring mode (horizontal/vertical/both/none), dr= Disable components by refdes (comma separated list) cfg= configuration file (in "key=value" format)

0 kommentar(er)

0 kommentar(er)